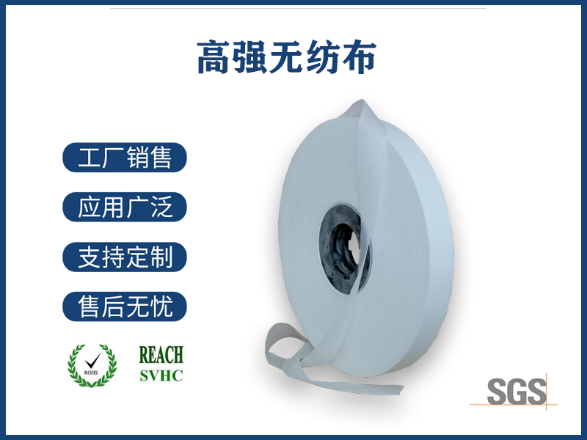

Non-woven fabrics, also known as non-woven textiles or simply “non-wovens,” represent a unique category of fabric that stands apart from traditional woven and knitted materials. Unlike their counterparts, these fabrics are not created by interlacing fibers in a regular pattern but instead are manufactured by a process that bonds or entangles fibers together. This innovative approach to fabric production has opened up a myriad of applications across various industries. One of the most notable features of non-woven fabrics is their versatility. They can be engineered for specific functions, making them incredibly adaptable. For example, non-wovens can be designed to be highly absorbent, which makes them ideal for use in products such as diapers and sanitary pads. Alternatively, they can be crafted to be strong and durable, suitable for use in industrial applications like geotextiles or filtration systems. The manufacturing process of non-woven fabrics is both efficient and cost-effective. Typically, it involves laying down a web of fibers and then bonding them together using chemical, mechanical, or thermal techniques. This method allows for high levels of automation and customization, leading to consistent quality and performance. Moreover, since the process does not involve the lengthy yarn-making steps required for woven fabrics, it is often faster and more economical. Another significant advantage of non-wovens is their sustainability credentials. Many non-woven materials can be made from recycled or biodegradable fibers, offering an environmentally friendly alternative to traditional synthetic fabrics. Additionally, because they can be produced with minimal waste, non-wovens contribute less to landfill mass than other types of textiles. As consumers and manufacturers alike become more environmentally conscious, the demand for eco-friendly non-woven products continues to grow. In the realm of healthcare, non-woven fabrics have proven to be indispensable. Their disposable nature and ability to act as effective barriers against bacteria and viruses make them perfect for medical applications such as gowns, masks, and drapes. During the COVID-19 pandemic, for instance, non-woven fabrics played a crucial role in the rapid production of personal protective equipment (PPE), highlighting their critical importance in modern medicine. Beyond healthcare, non-wovens have found uses in a wide range of consumer goods, from cleaning wipes and kitchen towels to packaging materials and agricultural covers. Their lightweight nature and ease of disposal make them particularly popular in single-use items. However, innovations in technology have also led to the development of non-woven fabrics that are washable and reusable, addressing concerns about sustainability and product longevity. Looking ahead, the future of non-woven fabrics appears bright. Advances in material science and engineering are continually expanding the potential applications for these versatile materials. Researchers are exploring new fiber compositions, bonding technologies, and functional finishes that could enhance the performance and sustainability of non-wovens even further. As a result, we are likely to see an increasing number of innovative products made from non-woven fabrics in the coming years. In conclusion, non-woven fabrics have revolutionized the textile industry with their unique properties and broad application spectrum. From healthcare to consumer goods, their benefits are undeniable. As technology progresses, non-wovens will undoubtedly continue to play a vital role in the development of new and improved products that cater to the needs of our modern world.

客服QQ

客服QQ