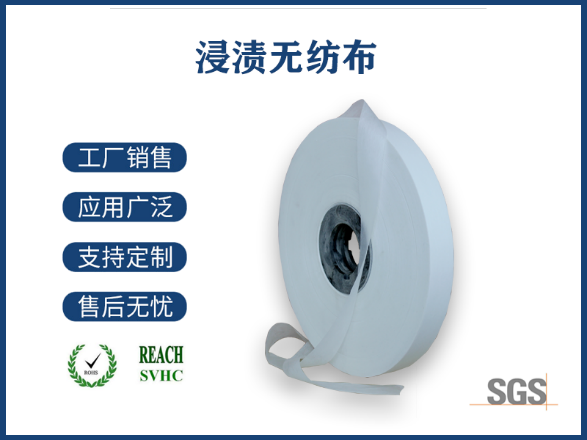

Title: The Advantages and Applications of Non-Woven Fabric Laminated Film in English Non-woven fabric laminated film, a revolutionary material in the world of textiles and packaging, combines the benefits of two distinct technologies to offer unique advantages. This article delves into the composition, properties, and diverse applications of non-woven fabric laminated films, particularly focusing on the English-speaking market. Understanding Non-Woven Fabric Laminated Film Non-woven fabric laminated film is a composite material that merges a layer of plastic film with a non-woven fabric through specialized adhesive or thermal bonding processes. This innovative combination results in a product that retains the strength, durability, and waterproof qualities of traditional plastic films while also incorporating the breathability, flexibility, and softness associated with non-woven textiles. The non-woven layer is typically made from fibers such as polypropylene (PP), polyester (PET), or a blend of both, whereas the film component can be derived from various polymers like low-density polyethylene (LDPE) or high-density polyethylene (HDPE). The laminination process ensures a secure bond between these layers, creating a versatile material suitable for numerous industries. Properties and Advantages One key advantage of non-woven fabric laminated films is their enhanced barrier properties. The integration of the plastic film provides excellent resistance against moisture, dust, and bacteria, making these materials ideal for hygienic applications such as medical gowns, surgical drapes, and food packaging. At the same time, the non-woven face retains air permeability, allowing for comfortable wear and preventing heat buildup—a crucial factor in personal care products like baby wipes and adult incontinence pads. Durability is another standout feature. The robust nature of the combined layers makes these films resistant to punctures, tears, and abrasions, extending the lifespan of products and ensuring they can withstand rigorous handling during transportation and storage. Moreover, they can be easily customized through printing and embossing techniques, adding aesthetic value without compromising functionality. Applications Across Sectors In the medical industry, non-woven fabric laminated films are used extensively for manufacturing disposable protective gear, including masks, gowns, and covers. Their fluid-resistant yet breathable properties make them perfect for maintaining aseptic environments while ensuring patient comfort. The food packaging sector also benefits significantly from this technology. These films serve as an effective barrier against contaminants while preserving freshness, thereby prolonging shelf life. Additionally, they provide a visually appealing finish that enhances product presentation on store shelves. For environmental sustainability initiatives, non-woven fabric laminated films offer a more eco-friendly alternative to conventional plastics due to their reduced thickness requirements and potential for recycling. As companies strive towards greener practices, this material’s biodegradability (depending on the polymer used) and lightweight nature contribute positively to reducing carbon footprints. In conclusion, non-woven fabric laminated films represent a versatile and sustainable solution across multiple industries. With continued advancements in manufacturing techniques and material science, we can expect even broader adoption and innovation in this field, further solidifying its position as a cornerstone of modern packaging and protective solutions.

客服QQ

客服QQ